ARTICLE: Monitoring triggers practice change

Over the last two seasons, the Serviced Supply Chains project has worked with a significant mango exporter to monitor several mango export consignments to China and South Korea. The consignments included one sea and seven air shipments in 2016-17, and three sea and nine air shipments in 2017-18. New monitoring technologies such as RFID-based Xsense (BT9 Ltd) and SIM-based SmartTraxx (Emerson) temperature loggers were used.

Monitoring and comparing the temperature profiles during the 2016-17 season identified the following risks to product quality in air shipments:

1. Temperatures typically increased through the supply chain. Contributing factors included:

- fruit dispatched from the shed being too warm

- temperature increases during the two-day surface freight from farm to Brisbane as port of departure, despite using refrigerated transport

- fruit not adequately cooled at the freight forwarder

- temperatures commonly increasing during the airfreight sector.

2. Often significant temperature differences between the outside of pallets and the inside and also within a pallet and across pallets based on the tray layer (vertical) and pallet position on the skid (horizontal). For example, in one air shipment to South Korea, temperature of trays in the middle of the pallet were 15°C warmer than trays in the top or bottom of the pallet.

Before the beginning of 2017-18 season, the exporter improved their temperature management strategies. Three critical control points at which temperature management could be improved were identified, i.e. at departure from the pack shed, at the freight forwarder and at the importer.

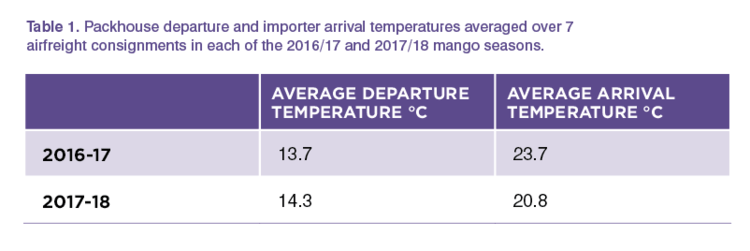

These improvements resulted in lower average temperatures on importer arrival in 2017-18 (Table 1), mainly because of improved temperature management at the freight forwarder, including re-cooling before aircraft loading if required.

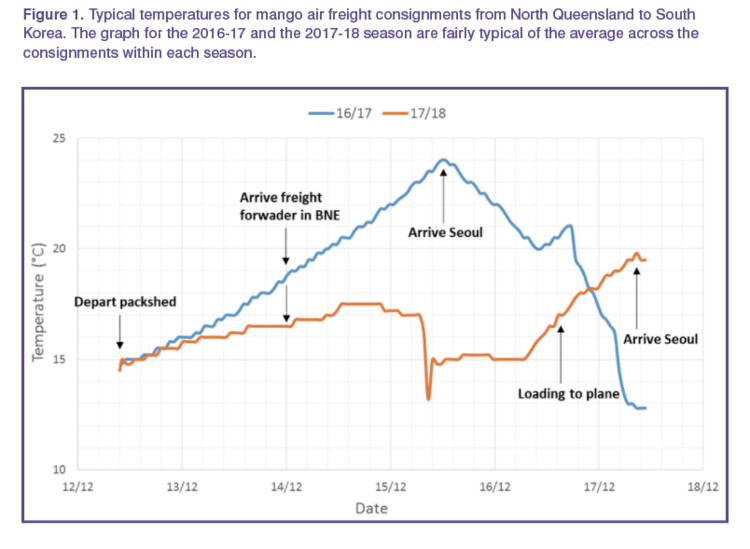

Figure 1 illustrates typical temperatures for a commercial air freight consignment to South Korea in the 2016-17 and 2017-18 seasons, which are close to the average conditions across the consignments monitored in each of the two seasons. In 2017-18, the arrival temperatures were lower largely because of cooling undertaken at the freight forwarder at the request of the exporter. Effective cooling at the packhouse and importer also helped manage these temperatures through the supply chain. The improved temperature management in the 2017-18 season also resulted in smaller temperature differences between the outside and inside of pallets.

The improved temperature management also led to a small, insignificant decrease in yellow skin colour and increase in firmness of the R2E2 fruit at importer arrival, which could improve shelf life.

For more information contact: Noel Ainsworth, Principal Supply Chain Horticulturist, at DAF; noel.ainsworth@daf.qld.gov.au or (07) 3708 8563.

Acknowledgements: The Serviced Supply Chains project is funded by the Hort Frontiers Asian Markets Fund, part of the Hort Frontiers strategic partnership initiative developed by Hort Innovation, with co-investment from the Department of Agriculture and Fisheries, Queensland (DAF), Department of Economic Development, Jobs, Transport & Resources (Victoria), Manbulloo (mangoes), Montague Fresh (summerfruit), Glen Grove (citrus), the Australian Government plus in-kind support from the University of Queensland and the Chinese Academy of Sciences.

Article submitted by Yiru Chen, Andrew Macnish and Noel Ainsworth from DAF.