Keeping Mangoes Fresher for Longer: Lessons from the Honey Gold Supply Chain

AM21000: Serviced Supply Chains II

John Agnew and Saeedeh Saberi, Queensland Department of Primary Industries (QDPI)

Alan Niscioli, Northern Territory Department of Agriculture and Fisheries (NT DAF)

Every grower knows how quickly mangoes can lose quality once they leave the farm. Piñata Farms, the team behind Honey Gold (HG) mango, has been working with the Queensland Department of Primary Industries (QDPI) in the Serviced Supply Chains II (SSC II) project to find out what is really causing quality loss and how to stop it. Together they monitored supply chains and trialled simple, data-driven fixes that growers can see working in the field.

The payoff?

Longer shelf life, fewer rejections, stronger returns for growers, less waste for retailers and better-eating mangoes for consumers.

Image (right). Gavin Scurr, Piñata Farms.

The challenge: short / variable shelf life

Piñata Farms supply about one million trays of HG mango each season from 27 growers across five regions. But keeping fruit at the right quality until it reaches market has been a big challenge. The SSC II project showed that transporting fruit at high temperatures and/or for longer durations generally leads to faster ripening, a shorter shelf life and a higher chance of rejection by retailers.

To get a clear picture, 59 consignments were tracked with real-time loggers between 2022 and 2025: first to spot the problems, and later to check if the fixes were working (Figure 2). The results of monitoring showed:

- Too warm in transit: 70% of NT consignments and 30% from Queensland (all from Mareeba) travelled at higher than the recommended 12–16°C in 2022-23.

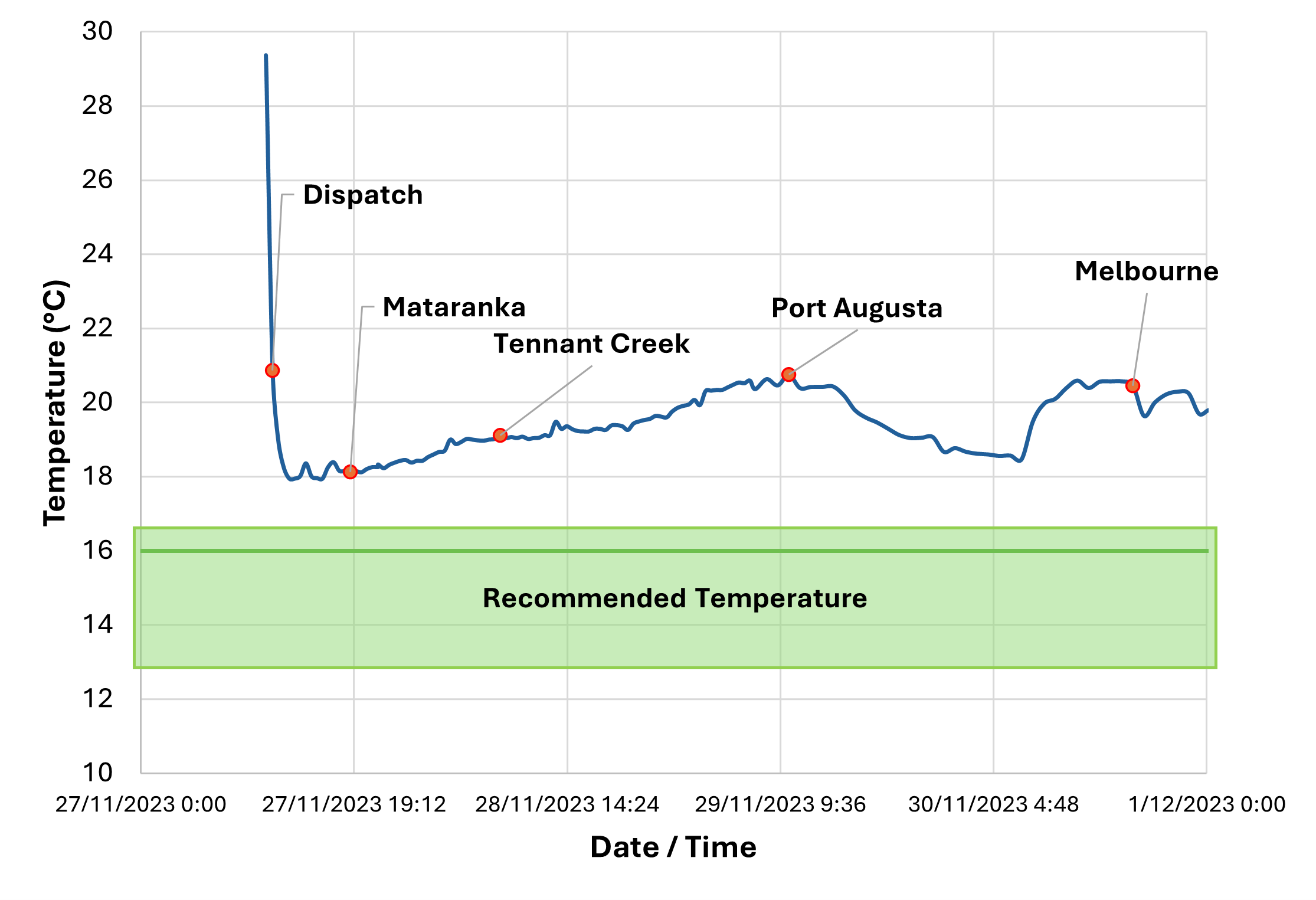

- Overripe on arrival: One Darwin consignment in November 2023 left at 20.3°C, averaged 19.3°C on the road, and arrived fully ripe (colour stage 6) with only four days of shelf life (Figure 3).

- Inconsistent temperatures: Across consignments, temperatures ranged from 7°C to 22°C, which meant variable quality and shelf life at arrival.

These problems hit growers and distributors hard, not just in fruit quality but also in lost returns.

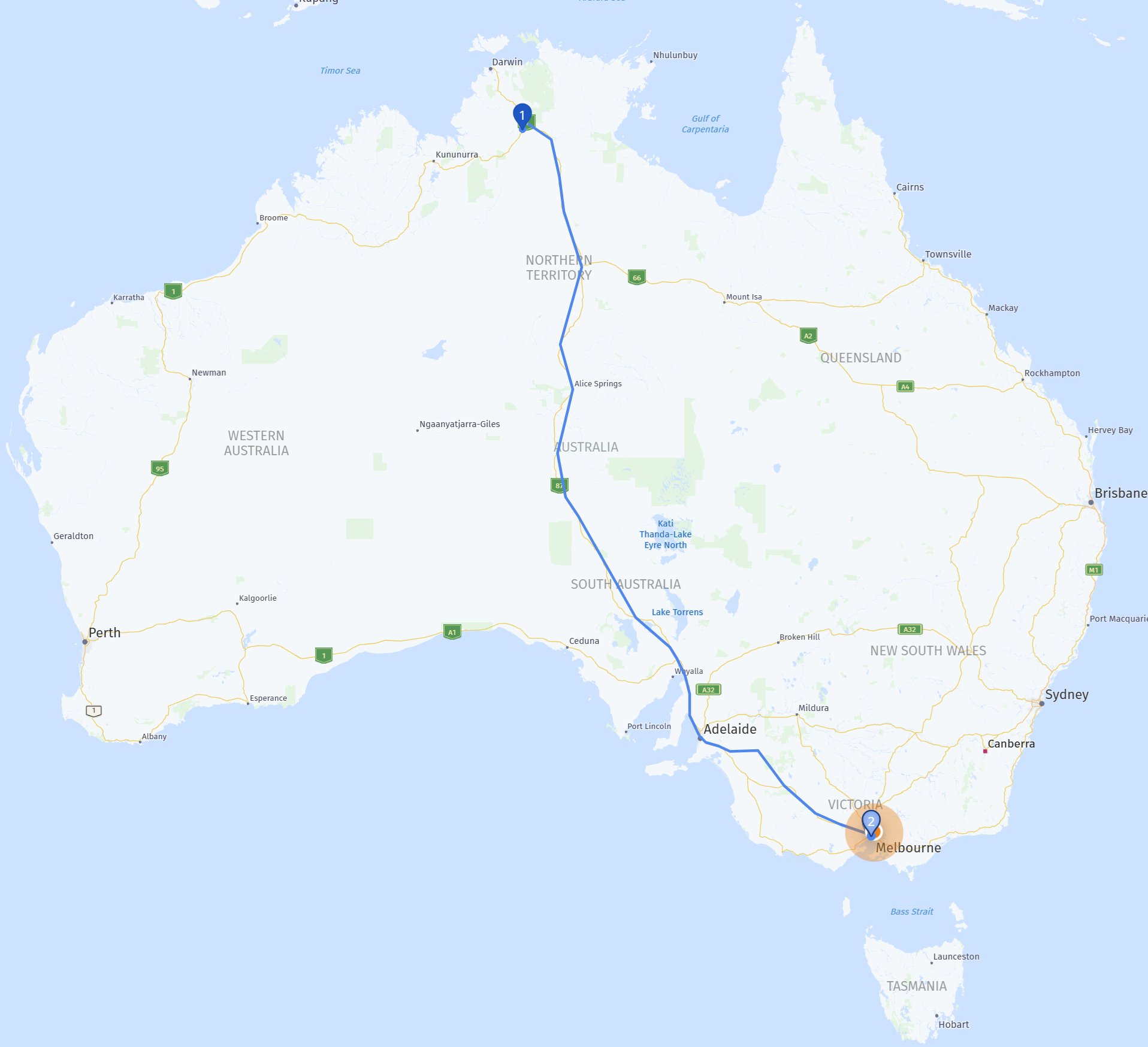

Figure 2. Real-time logger used in a consignment of Honey Gold mangoes (left); tracker dashboard showing the transport route of a consignment from Katherine, NT, to Melbourne in December 2023 (right).

The solution: smarter cold chain practices

Temperature monitoring showed exactly where things were going wrong; and how they could be fixed. In the past, real-time loggers were mainly used just to check when trucks would arrive. Through the SSC II project, Piñata Farms began using them as a tool to protect fruit quality and shelf life. They made three key changes:

- Pre-dispatch cooling: Fruit was cooled to 15°C before leaving the shed, giving it the best start for the journey.

- Real-time monitoring: Every consignment carried a logger, so temperatures could be tracked from packing to market.

- Working with transporters: Piñata worked closely with transport companies to keep trucks in the 12–16°C range, and chose partners who consistently delivered the right conditions.

Figure 3. Temperature of Honey Gold mango consignment from Darwin to Melbourne, November 2023 (left). Tray of fruit from Darwin consignment collected by assessors in Melbourne showing advanced ripening (right).

The results: improved quality / shelf life

The benefits showed up quickly. In December 2023, a consignment from Katherine to Melbourne left at 15.1°C and held steady at around 15.7°C during the trip. On arrival, 60% of fruit was still at early colour stages (2–3), and shelf life stretched to an average of 13 days, meeting market needs and showing the value of better temperature control.

Table 1 tracks results from Central Queensland over three seasons. The data tells a clear story:

- Average consignment temperature dropped from 15.4°C to 13°C,

- Transit times shortened by 1.5 days,

- Median shelf life jumped from 11 days (2022) to 15 days (2024).

| Season | Average Temperature along Supply Chain (°C) | Average Duration in Supply Chain (day) | Average Shelf Life (day) |

| 2022 | 15.4 | 5 | 11 |

| 2023 | 14.5 | 7 | 11 |

| 2024 | 13 | 3.5 | 15 |

Table 1. Changes in the temperature, the number of days in the supply chain and shelf life of Honey Gold consignments sourced from Central Queensland over three seasons. The values shown are medians of consignments in each season.

According to an economic analysis, putting SSC II findings into practice means Piñata Farms can achieve:

- Longer shelf life and better fruit quality at market.

- Fewer rejections: down from 1.5% to 0.5%.

- Higher sales: lifting annual revenue by around 7.5%, plus another 0.5% from more consistent quality and known shelf life.

- Better supply chain visibility: with real-time monitoring, problems can be spotted and fixed quickly.

Reflecting on the project's impact, Gavin Scurr said, "The project delivered real benefits by improving communication with growers and showing that transport and storage temperatures can be lowered without compromising eating quality." He added, "Learning from this project will lead to more consistent fruit quality and greater customer satisfaction."

Contact

Dr Andrew Macnish

Supply Chain Innovation Team

Department of Primary Industries

0475839609

Andrew.macnish@dpi.qld.gov.au

The information contained herein is subject to change without notice. The Queensland Government shall not be liable for technical or other errors or omissions contained herein. The reader/user accepts all risks and responsibility for losses, damages, costs and other consequences resulting directly or indirectly from using this information.

The Serviced Supply Chains II project (AM21000) is funded by the Hort Innovation Frontiers Fund, Avocado and Strawberry research and development levy, and contributions from the Australian Government, with co-investment from the Department of Primary Industries, Queensland (DPI), Department of Energy, Environment and Climate Action, Victoria (DEECA), Department of Agriculture and Fisheries, Northern Territory (DAF), Department of Primary Industries and Regional Development, Western Australia (DPIRD), Pinata Farms Pty Ltd and Summerfruit Australia Ltd. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The quality and shelf life assessments were conducted by trained assessors from Rudge Produce Systems, and the economic analysis was undertaken by Michael Clarke from AgEconPlus.