Temperature management throughout the supply chain—how is industry tracking?

In the 2019/20 season Australian Mangoes, with the assistance of Escavox, tracked 82 mango consignments to gain a better understanding of the conditions in which mangoes travel on their journey from the packhouse to the main markets across Australia.

The 2019/20 season was the first in a three-season initiative that seeks to improve the overall supply chain performance of the industry. The data generated by tracking mangoes on their journey from packhouse to the supply chain over these three years will inform and guide industry in the development of Best Practice Resources.

LOCATIONS AND TRANSIT DWELL TIME

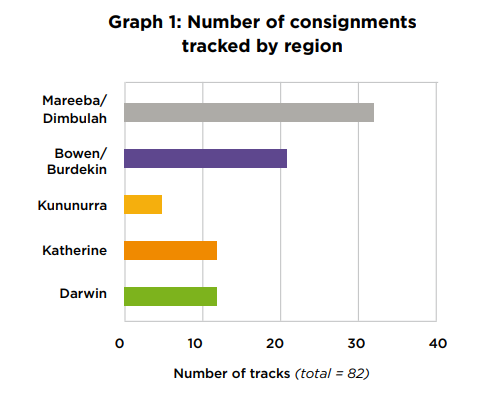

21 growers from most of the key growing regions were involved (see Graph 1) in this initiative this season. The end destinations included all the major markets with consignments reaching Brisbane, Sydney, Melbourne, Perth, Adelaide and even Alice Springs.

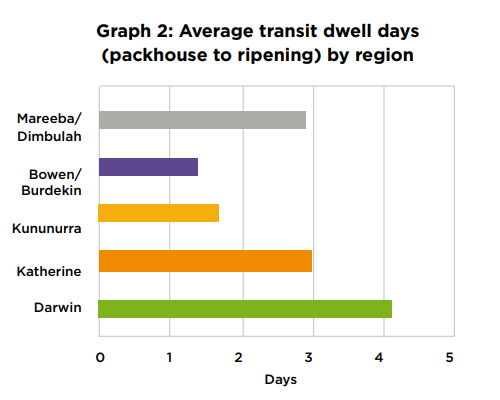

As expected, the average transit dwell time from packhouse to ripening was the highest at 4.1 days for Darwin, followed by Katherine and Mareeba/Dimbulah at 3 and 2.9 days respectively and Kununurra and Bowen/Burdekin sitting at 1.7 and 1.4 days respectively (see Graph 2).

TEMPERATURE PERFORMANCE

Each track was assessed against the industry recommended temperature range for the three key legs in the supply chain:

At packhouse: minimum 12 ̊C*

Packhouse to ripener (via transport): 12 ̊C-18 ̊C

At ripener (storage and ripening process): 12 ̊C-22 ̊C.

The data shows supply chain performance across the tracks ranged from very poor, where the product was not pre-cooled and travelled outside optimum conditions for the complete journey to ideal tracks.

Only 15% (12 of 82 tracks) of consignments stayed within the recommended temperature range throughout the whole journey. More than three-quarters of all tracks experienced temperature issues that were inconsistent with best practice.

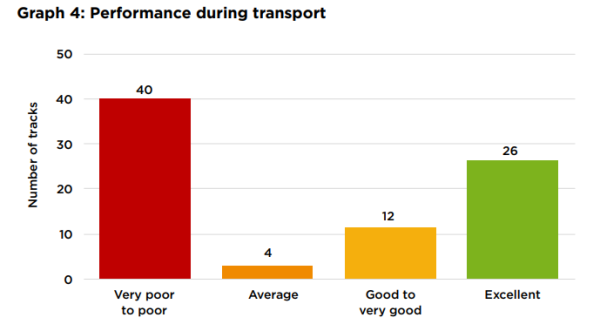

Overall, of the 82 tracks analysed, in terms of temperature performance the following assessments have been made:

49% were very poor to poor (40 of 82 tracks)

15% were average (12 of 82 tracks)

22% were good to very good (18 of 82 tracks)

15% were perfect (12 of 82 tracks).

*Note: In measuring performance of the supply chain, a maximum of 40 ̊C is used as the upper limit for temperature in the packhouse leg of the supply chain. This recognises the practical limitations of the supply chain in that fruit is unavoidably exposed to ambient conditions at different times in the packhouse.

PACKHOUSE

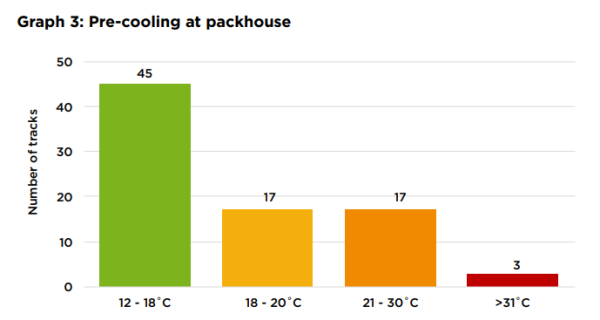

Lack of pre-cooling of fruit was identified as a key imperative to poor temperature performance; with almost half of all loads not pre-cooled sufficiently (see Graph 3). For a couple of growers, pre-cooling was taking place at the transporter’s depot. Pre-cooling is critical to help preserve quality and prolong shelf life. Even if fruit is to be partially ripened in-transit, it should be cooled down to 18°C.

TRANSPORT AND RIPENING

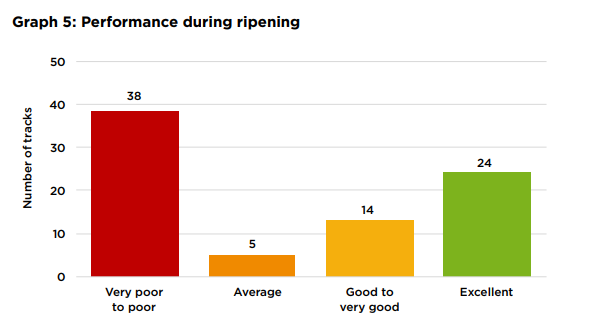

Consignments during transport (Graph 4) and ripening (Graph 5) performed similarly with almost half of all tracks performing poorly to very poorly. Industry needs to get a greater understanding of what the impact and ultimately what the cost of this non-compliance is on growers’ bottom line. Australian Mangoes will investigate the options to best collect this type of information for the upcoming season.

ABOUT THE TRACKING PROCESS

By monitoring temperature across existing and new supply chains, growers are able to identify where best practice isn’t followed and any critical control points where change is required to ensure best practice temperature is followed. If you wish to be involved next season, please contact your local Industry Development Officer (IDO). The process of tracking products is simple. Your IDO will provide you with Escavox trackers that simply need to be included in pallets at the packhouse. Instructions will be given on where to place trackers in the pallet and number of trackers per load, as well as stickers for identification of trays so trackers can be easily extracted after the ripening/transit process. Participating growers/packers receive their own reports on the performance of their supply chain. There are procedures in place to protect your data, knowing that some data is commercially sensitive.

This activity is being undertaken as part of MG1700 Building Best Management Practice Capacity for the Australian Mango Industry which is being funded by Hort Innovation, using the mango industry research and development levy and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.