Using data to define best practice in the supply chain

This season (2019/20) Australian Mangoes has started tracking mango consignments to gain a better understanding of the conditions in which mangoes travel on their journey from the packhouse to the main markets across Australia.

![]()

Escavox tracker and sticker

This is year one of a three-year initiative which seeks to improve overall supply chain performance of the industry, knowing that poor postharvest temperature management and extended time in the supply chain are two of the most critical elements that negatively impact produce quality and consequently consumer demand, the aim of this activity is to establish a benchmark of industry performance against industry best practice.

“By constantly measuring how our supply chains perform we will be able to identify areas where we need to do further work to get the quality outcomes that our industry needs, which will grow confidence and demand for mangoes,” said Australian Mangoes CEO, Robert Gray.

“Over this season, it is the intent to track 200 journeys of mangoes from all regions of Australia to the major markets, to better understand temperature and dwell time. Escavox, a company specialising in fresh produce tracking, is helping in this process.

“By developing our pool of data, it will be possible to measure supply chain conditions against best practice standards. This will give us objective insights into supply chain performance and identify where issues exist, the scale of these issues and where further research and development (R&D) or infrastructure investment may be needed,” he said.

WHAT THE DATA TELLS US SO FAR

Results from the first 30 completed tracks have been collated. Nearly all tracks of these originated from the Northern Territory, whilst end destinations included Adelaide, Sydney, Melbourne and Perth.

In assessing the tracks, three key legs in the supply chain and associated temperatures were identified as the basis for assessment:

- At packhouse: minimum 12 ̊C *

- Packhouse to ripener (via transport): 12 ̊C-18 ̊C

- At ripener (storage and ripening process): 12 ̊C-22 ̊C.

* Note: In measuring performance of the supply chain, a maximum of 40 ̊C is used as the upper limit for temperature in the packhouse leg of the supply chain. This recognises the practical limitations of the supply chain in that fruit is unavoidably exposed to ambient conditions at different times in the packhouse. After this season we will review our critical temperature bands and adjust if necessary.

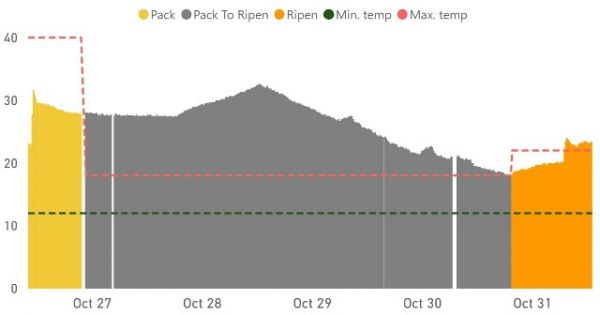

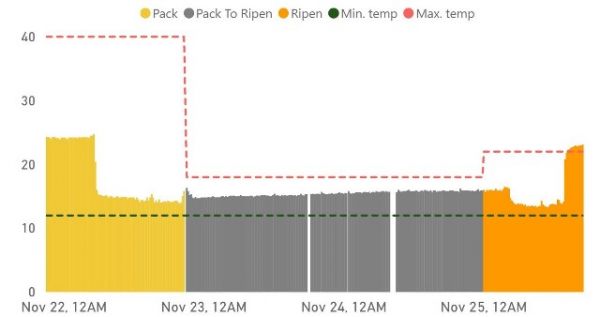

The data shows supply chain performance across the tracks ranged from very poor, where the product was not pre-cooled and travelled outside optimum conditions for the complete journey (see Graph 1), to tracks that were near ideal (see Graph 2).

Northern Territory to Sydney Track #1

Graph 1: A track from the Northern Territory to Sydney (October 2019)

Northern Territory to Sydney Track #2

Graph 2: A track from the Northern Territory to Sydney (November 2019)

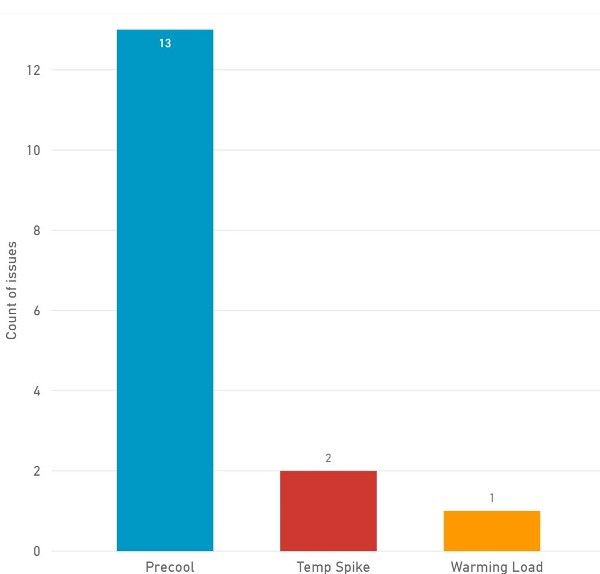

Of the 30 mango tracks (journeys) reported so far, more than half experienced temperature issues that were inconsistent with best practice. Most notably, the lack of pre-cooling of fruit was by far the greatest issue, with a third of all loads not precooled sufficiently (see Graph 3).

Graph 3: Incidence of temperature issues experienced by the 30 mango supply chain tracks reported.

Overall, of the 30 tracks analysed, in terms of temperature performance the following assessments have been made:

- 43% were very poor to poor (13 of 30 tracks)

- 23% were average (7 of 30 tracks)

- 33% were good to very good (10 of 30 tracks)

In addition to the full data sets for each track, Escavox also provided live data heat maps of each individual journey. Ideally all journeys should be represented by green dots, showing that produce is travelling in optimum conditions for the specific leg of the supply chain (see Image 1). However, in most cases, yellow and red dots on maps indicated less than ideal temperature conditions (Image 2).

Image 1 (Top) and 2 (Bottom): Image 1 showing a track that is travelling at optimum conditions as indicated by green dots. Image 2 showing a track that has travelled at sub-optimal conditions, as indicated by yellow and green dots.

WHERE TO FROM HERE

The next phase of this activity will track produce from Queensland and Western Australia. At the end of the season, Australian Mangoes and Escavox will undertake a full review of all data collected and provide an update on overall industry supply chain performance as well as reporting the insights the data has provided.

Australian Mangoes will then consider how supply chain and other data might continue to be used to assist in improving the overall quality performance of the industry.

ABOUT THE TRACKING PROCESS

The process of tracking products is simple. Australian Mangoes provides you with Escavox trackers that simply need to be included in pallets at the packhouse. Australian Mangoes will provide guidance on where to place trackers in the pallet and number of trackers per load, as well as stickers for identification of trays so trackers can be easily extracted after the ripening process.

The rest of the process is fully automated and Escavox provides the analytics so supply chain performance can be easily reviewed. Participating packers receive their own reports on the performance of their supply chain.

If you would like to be involved in this initiative and are still packing, it’s not too late, just contact the Australian Mangoes office to get involved on 07 3278 3755. There are procedures in place to protect your data, knowing that some data is commercially sensitive.

For further information on pre- cooling check out the Mango Ripening Manual

This activity is being undertaken as part of MG1700 Building Best Management Practice Capacity for the Australian Mango Industry which is being funded by Hort Innovation, using the mango industry research and development levy and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.